Wood-burning stoves have evolved from simple wood-fired heaters to sophisticated, high-efficiency appliances that not only heat homes but also add an incredible ambience that no other fire can match. Yet many homeowners and even professionals sometimes deal with smoking stoves – fumes escaping into living spaces instead of up the chimney. Smoke is more than a nuisance: it is a sign of incomplete combustion, potential safety risks and wasted energy.

The Science behind the Smoke

Smoke is the visible part of wood combustion gases. When wood burns, complex chemical reactions convert cellulose, hemicellulose and lignin into heat, water vapour, carbon dioxide and other various gases. In ideal combustion, nearly all volatile compounds oxidise, leaving little visible smoke. Poor combustion, however, releases unburned particles and gases that appear as smoke. Common reasons for inefficient combustion include insufficient temperature, inadequate oxygen supply and damp or unseasoned (wet) wood. You can learn more about the chemistry of wood here.

Ecodesign wood-burning stoves achieve cleaner combustion by capturing and burning these gases.

Why Stoves Smoke: Common Causes and Fixes

Damp Wood:

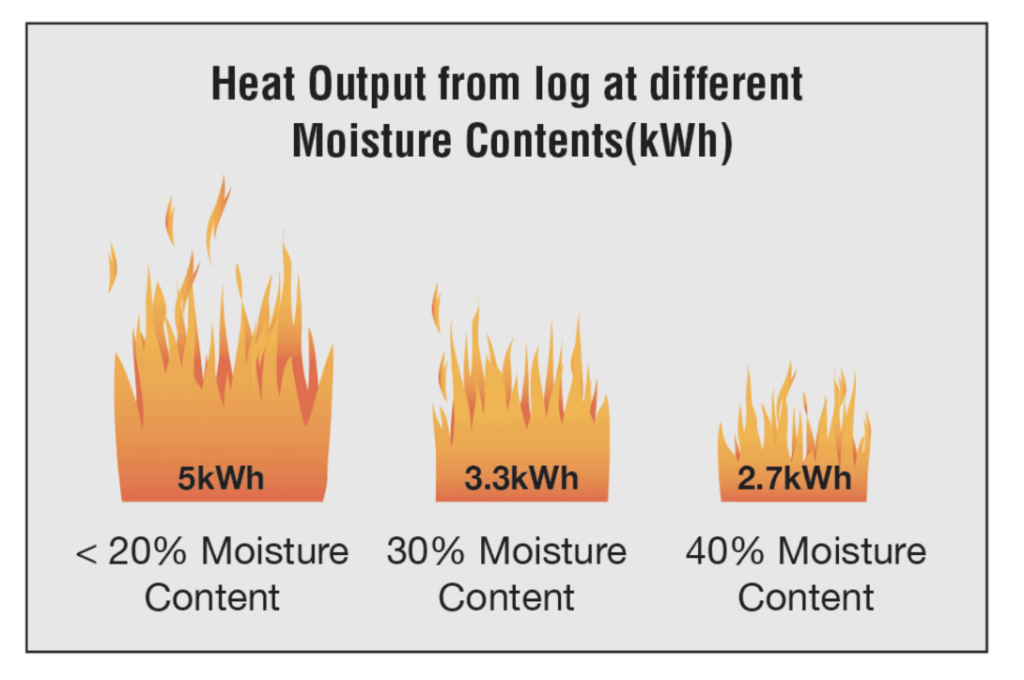

The most frequent offender of excess smoke is damp wood. Freshly cut logs contain a high moisture level; as the wood heats, this water boils and cools the fire, preventing complete combustion. Wood should be seasoned for at least six months, or up to two years for hardwood like oak, and have a moisture content below 20 per cent, which can be checked with a moisture meter. Wet or green wood is the primary cause of excessive chimney smoke. Burning damp wood produces less heat and more creosote, a tar‑like residue that accumulates in chimneys and increases fire risk. The use of dry, split wood (marked “Ready to Burn”) can reduce emissions by approximately 50 per cent.

Troubleshooting: Always use seasoned wood. Split logs into pieces less than six inches in diameter, stack them off the ground and cover the top while allowing air circulation. Check moisture with a meter; ready‑to‑burn logs should register under 20 per cent. Avoid burning construction waste or treated wood, which can release toxic fumes and damage stove components.

Below shows the heat output at different moisture content levels:

Poor Draft and Flue Problems

A wood stove relies on draft, hot gases rising up the chimney, to pull fresh air into the firebox and expel smoke. The draft depends on the temperature difference between the flue and outdoor air, as well as the chimney’s height and construction. A weak draft will allow smoke to spill into the room. Draft strength increases with chimney height; cold chimneys or insufficient height can produce inadequate draft. Obstructions, such as bird nests, soot, or creosote deposits, also impact airflow.

Troubleshooting: Regularly inspect and clean the flue. Have a certified chimney sweep remove creosote and check for blockages. Discover more about what a chimney sweep does here. If the chimney is too short, consider extending it; many experts recommend at least 4.5 meters (15 feet) above the stove for strong draft. When starting a fire, pre‑warm the chimney by burning a rolled‑up newspaper near the flue to create an initial draft. Never letting fires smoulder overnight because smouldering produces thick smoke and increases creosote deposits.

Negative Pressure and Poor Air Supply

Modern homes are increasingly airtight due to insulation and double glazing, which can starve a stove of combustion air and lead to negative pressure. When the pressure in the room falls below outside pressure, due to extractor fans or other appliances exhausting air, airflow may reverse, forcing smoke down the chimney.

Troubleshooting: Ensure there is an adequate air supply to the room. Some stoves can be fitted with an external air kit, supplying combustion air directly from outside. Avoid running extractor fans, such as kitchen hoods or bathroom fans while operating the stove. Opening a window slightly can relieve negative pressure and restore draft, particularly in airtight buildings.

Chimney Designs & Weather Conditions

Chimney height and insulation have significant effects on draft. As mentioned, chimneys that are too short fail to create sufficient suction. Conversely, very tall, uninsulated chimneys cool flue gases so much that they slow down and sink. Wind and weather can also cause downdrafts; high winds can push smoke back down the chimney, especially when the house is exposed. Extremely cold outdoor temperatures may reverse airflow through twin‑walled metal flues.

Troubleshooting: Verify that your chimney meets the manufacturer’s recommended height and is not excessively long. Insulate metal flues with vermiculite or an insulating sleeve to maintain internal temperature. Consider installing a chimney cap or cowl to reduce downdrafts; wind-directional caps can enhance performance in exposed locations. On very windy days, adjust the stove’s air control to maintain a strong fire and watch for signs of downdraft.

Blocked or Faulty Baffle Plate

Within the stove, a baffle (also called a throat plate) slows the exit of hot gases and reflects heat back into the firebox. If the baffle is misaligned or damaged, it may obstruct the flue opening or cause gases to cool prematurely, resulting in reduced efficiency. A poorly positioned baffle or broken part can cause smoke, and if the baffle is correctly positioned yet smoke persists, the problem likely lies in the chimney.

Troubleshooting: Ensure the baffle sits correctly on its supports. Refer to your stove’s manual for correct installation. Replace warped or cracked baffles promptly; using a damaged part reduces efficiency and increases emissions. Also check door seals, firebricks and grates; worn components compromise airflow and combustion.

Creosote Build‑Up and Lack of Maintenance

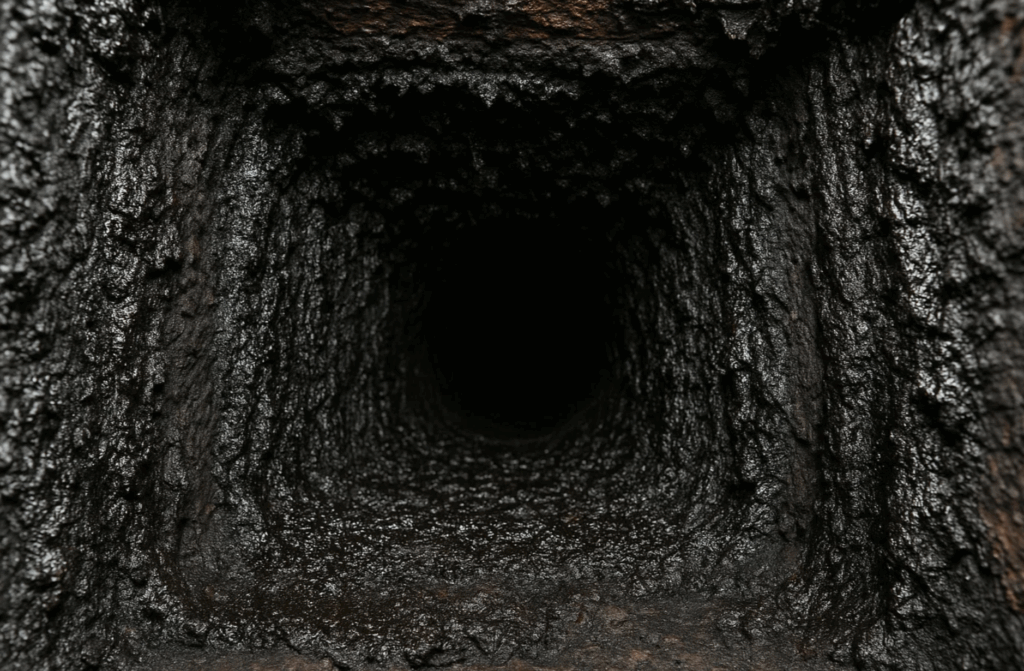

Incomplete combustion, particularly from low fires or damp fuel, leads to creosote, a sticky, highly flammable residue, coating the chimney. Accumulated creosote narrows the flue and can ignite a chimney fire. Creosote build‑up is a common cause of blocked chimneys.

Troubleshooting: Schedule a professional chimney cleaning at least once a year as a minimum, or more frequently if you burn wood regularly. Use dry wood and maintain high combustion temperatures to minimise creosote formation. If you notice black, tarry deposits in your stove or creosote flakes falling into the firebox, stop using the appliance until it is inspected.

Cold Starts and Insufficient Kindling

Starting a fire in a cold stove and flue requires extra care because the draft is weak. Without sufficient heat and combustible material, smoke may escape when the fire is first ignited.

Troubleshooting: Use plenty of dry kindling and open the stove’s air vents fully when lighting the stove. Some leave the stove door slightly ajar for the first few minutes to allow ample oxygen and establish a draft, if permitted by the manufacturer. Once the fire is burning vigorously and the draft is established, close the door and adjust the air control for efficient operation.

User Error and Air Control Misuse

Users sometimes close the air intake too early in an attempt to prolong the burn or reduce heat output, but doing so starves the fire of oxygen and leads to incomplete combustion. Similarly, overloading the firebox with logs reduces airflow between pieces and promotes smouldering. Chimney smoke often signals that the stove is not being operated correctly.

Troubleshooting: Operate the stove with air vents fully open until the fire is well established. Adjust the air control gradually to maintain a bright, lively flame rather than dampening it excessively. Avoid over‑filling the firebox; leave space between logs for air circulation.

Combustion Efficiency and Health Considerations

Beyond the inconvenience of smoke and soot, poor combustion harms health and the environment. Wood smoke contains fine particulate matter (PM2.5), carbon monoxide (CO), volatile organic compounds and polycyclic aromatic hydrocarbons.

Addressing Air Quality Concerns & Ecodesign:

The Ecodesign regulations took effect on 1 January 2022, setting minimum seasonal efficiency requirements and limits on carbon monoxide, nitrogen oxides, particulate matter, and organic gaseous compounds for new stoves. As a result, only Ecodesign‑compliant stoves can now be manufactured or sold. These appliances achieve at least 75 per cent efficiency and include technologies such as clean-burn secondary combustion, air-wash systems that keep glass clear. Owners of pre‑2022 stoves may continue using them, but should be aware of restrictions in smoke control areas.

How Ecodesign Stoves Achieve Low Emissions

Ecodesign stoves incorporate design enhancements such as insulated fireboxes, baffles that promote secondary combustion, and meticulously engineered air controls that ensure the right balance of primary and secondary air. Many models, including those in the Charlton & Jenrick range, feature air‑wash technology, which channels clean air across the inner surface of the glass and into the combustion zone, keeping the glass clear and ensuring gases are burned.

Summary:

A smoking wood-burning stove is a sign that something is wrong, often due to moisture in the fuel, inadequate draft, or incorrect operation. By understanding the principles of combustion and airflow, homeowners can enjoy the warmth and ambience of their stove while minimising smoke, health risks and environmental impact. Modern Ecodesign stoves, combined with dry fuel and proper maintenance, provide a path towards cleaner, more efficient home heating. Whether you are a homeowner troubleshooting an older stove or a professional advising clients, the message is clear: burn clean, maintain your stove and chimney diligently, and consider upgrading to the latest generation of low‑emission appliances. Remeber thse key points:

Use dry, seasoned fuel: Only burn wood with a moisture content under 20 per cent; splitting and storing correctly will achieve this. Avoid burning waste or wet wood; it creates smoke and creosote.

Maintain proper draft: Ensure the chimney is tall enough, well-insulated and free of obstructions. Pre‑warm the flue for cold starts.

Provide an adequate air supply: Avoid creating negative pressure. Supply combustion air through an external air kit or slightly open a window. Also, avoid running extractor fans while the stove is lit.

Operate correctly: Follow manufacturer instructions for lighting and air control. Do not choke the fire by closing vents too soon or over‑filling the firebox.

Regular maintenance: Inspect and sweep the chimney annually; replace worn seals, baffles or firebricks. Install carbon monoxide detectors and smoke alarms.

Consider upgrading: Modern Ecodesign stoves deliver higher efficiency, lower emissions and regulatory compliance. They pair best with certified dry fuel and proper installation.