The simple answer is yes!

The simple answer is yes!

Sadiq Khan stirred up a great deal of debate and some would say confusion when towards the end of 2017 he announced a clamp down on solid fuel appliances in the capital.

The main issue was that Sadiq Khan wrote to the Environment Secretary Michael Gove, to ask for more powers that would enable him to introduce “zero-emission zones” in London, where the burning of wood and coal would be totally prohibited.

Confusion and Over Reporting:

The main confusion comes from the reporting of this “zero-emission zone”. To start with, the changes that are being discussed, are related to using solid fuel open fires (a significant issue in London) and does not relate to high efficiency stoves, such as those found in the Charlton & Jenrick range. Furthermore, these changes are only relevant to certain parts of London only, no other parts of the UK.

A press release from Sadiq Khan on the subject reads,

A press release from Sadiq Khan on the subject reads,

“The Mayor believes that more should be done to empower consumers to make the right choice, including better information at the point of sale and mandatory labelling of products that are legal to use in smoke control areas.”

In a recent article, we discussed the key elements of Ecodesign ready stoves, and how they will help contribute to a cleaner, greener environment.

All Ecodesign ready stoves are clearly labelled as such. Furthermore the current CE and DEFRA approved stoves are highly efficient and clean burning, to a standard. However Ecodesign Ready, which will become a legal requirement in 2022, will improve the current standards. To qualify for the SIA ‘Ecodesign Ready’ label, which all Charlton & Jenrick Purevision stoves currently are, a stove must be independently tested by an approved test laboratory and meet the emissions and minimum efficiency criteria for ‘Ecodesign Ready’. The test results must then be verified by HETAS and it can then be listed on their website as ‘Ecodesign Ready’.

While CE testing deals with CO (Carbon Monoxide) levels, along with certain sized particulates and DEFRA deals with efficiency, ‘Ecodesign Ready’ includes standards for CO, NOx (Nitrogen Oxides), OGC (Organic Gaseous Compounds), particulates and efficiencies which will help stove manufacturers make safer and more efficient products that will in turn cause less air pollution.

How We Make an Ecodesign Stove:

Here is an insight into some of the things we pay specific attention to, in making a highly efficient Ecodesign ready stove:

.

- Gasification: A solid log does not just burn by itself, it needs to be broken down into constituent parts by thermally degrading it into gases and solid matter. The solid elements act like a sort of wick in a candle, and all the gases produced burn as bright attractive flames above the fuel within the firebox. To achieve this thermal breakdown it is important to get the right burning conditions, especially the retention of heat within the fuel bed.

. - Secondary Air: This is usually present in modern wood burners, primarily for the objective of maintaining clean glass as an air wash, but secondary air is an important part of burning off the gases produced by logs within the combustion chamber. In fact a portion of the secondary air can act as primary air, as well in promoting the gassing off from the solid logs during the burn cycle.

. - Tertiary Air: This is probably the development that has most reduced smoke emissions over recent years, and is in fact extra secondary combustion air by a different route. The entry points are usually above the fuel in the rear of the firebox and continue combustion flames once the majority of primary and secondary air have done their job.

. - Mixing Fuel & Air: This is often overlooked but it is critical to mix the fuel and air well inside the firebox. Air that pays no part in the combustion process just cools the firebox, and carries away heat into the flue, hence the poor thermal efficiency of an open fire. The entries for the various air injection stages, plus the shape of the firebox itself contribute to the mixing and therefore completeness of combustion.

. - The Conditions Inside The Firebox: These are critical to the effects of all the foregoing stages. For example if heat is lost too quickly, then flames will stop burning before combustion is completed. Also no matter how hot they are, pockets of unburned gases with no oxygen present cannot burn any further.

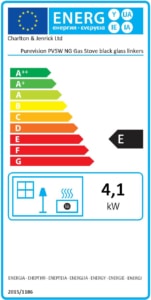

Energy Labelling:

Energy Labelling:

To help consumers make more of an informed choice about the efficiency of the appliance they are buying, which supports the statement made by Sadiq Kahn, quoted above, energy labelling is being implemented through The Energy Labelling Directive.

This was introduced to help consumers make a more of an informed choice on solid fuel systems and packages on sale today

All newly manufactured solid fuel appliances sold in retail outlets and from suppliers after the implementation dates will have attached to the front of them a copy of the energy label, providing technical details and information on the appliance energy rating and capabilities.

.

Implementation Dates

The dates of implementation for when the Energy Labelling Directive becomes mandatory are:

.

- Independent Boiler Appliances – 1st April 2017

- Roomheater Stoves – 1st January 2018

Whether it’s talk of a “Zero Emission Zone” in London, debate over the cleanest way to heat a home, or discussion over energy labels, there is a dramatic and much needed shift towards the environmental impacts of various heating options, and a drive for a cleaner, greener environment.

Ecodesign ready stoves are already helping make a positive contribution to this, and in the future will continue to do so. Energy labels will also play a key part in helping consumers not only make informed choices over their solid fuel heating appliances, but will also help towards front of mind awareness, over the importance of fuel efficient systems and why they are so important.