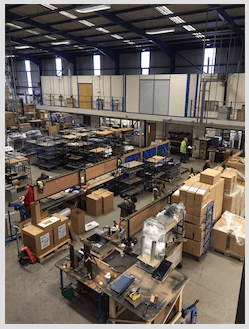

Gas Fire Assembly Line:

This is the gas fire assembly line in Telford, Shropshire, where a number of specially trained staff have specific jobs that range from:

- Hand building various elements of our fires.

- Testing all safety critical parts such as the gas valves.

- Providing essential quality control before a fire leaves the assembly line

Fire Assembly Construction:

Our trained staff carefully build the main part of a gas fire, taking the time to ensure the correct fitment and finish.

Each fire we build by hand is checked, not only when it is finished, but also when the build is in process.

Some parts of a gas fire are only visible during the initial stages of construction, and so it is essential that during this stage, we pay close attention to the quality, fitment and finish of the fire – not just when it is a finished product. This ensures a superbly build, reliable fire.

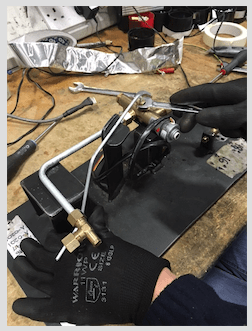

Gas Valve Testing:

The valves of a gas fire are safety critical, and form a key part of the fire. Without these you would have no flame!

Gas valves are responsible for delivering and controlling the gas to be ignited. Our staff take the time to visually inspect all elements of the valves, and then once they pass a very detailed visual examination, they are then tested with actual gas and fire on one of our specialist testing benches.

As with the main fire construction, taking the time to ensure the valves are to the highest standard, and are fault free helps ensure a safe, reliable fire for you to enjoy.

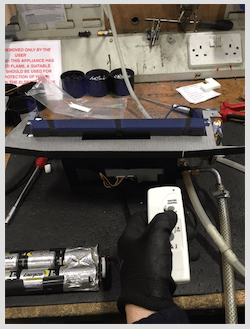

Further Valve & Ignition Testing:

Once the visual inspection of the valves are complete, we then test them, again by hand to see how they perform at the most critical stage – when the fire is in operation.

At this stage we test the valves at different rates, from a low flame setting to a high flame setting, and everything in-between.

During this stage we use and test the remote control to ensure a safe and reliable flame, that is working as intended.

ODS Leakage Room:

We have a specially designed leakage room, where we test each model in our range, to ensure it detects and then, most importantly, shuts off when carbon monoxide reaches 200 parts per million.

Carbon monoxide is an odourless, colourless gas, which can kill you. When something is burned it produces carbon monoxide. This will not cause an issue with a correctly fitted fire. However, a badly fitted fire or one, which is faulty or not serviced correctly could pose a serious health threat.

For your own safety all are fires shut off when excessive carbon monoxide is detected.

Limestone & Granite Finishes.

Many of our fire surrounds are made from limestone or granite. We offer a bespoke service, where our stonemasons can alter the fire to fit your exact requirements.

Our stonemasons spend a great deal of their time ensuring either the limestone or granite is prepared to the highest standard for the vast range of fire surrounds we sell, either separately or as a suite, which includes both the fire and surround.

Our stonemasons are master crafts people, who are passionate about their job. A passion, which reflects in the finish of our surrounds.

All Ready for Shipping:

Once our fires have been tested, built and checked, and our team are totally happy with them, they are ready to be distributed to our showrooms around the UK.

Each fire is carefully packed and put on a secure pallet and placed in our dispatch area.

We wave goodbye to each fire, as it makes it’s onward journey to the relevant showroom, and then to it’s home, where it should give many years enjoyment to the customer, who have decided to buy from Charlton & Jenrick.