Are you familiar with the anatomy of a stove and how they work? Do you know the difference between your air wash and firebox? What about tertiary air?

When you take to stove ownership, you may become familiar with the various parts of a stove, what they do and how they operate, but not everyone does – especially if your stove is only used on occasion or you simply don’t have the interest in the technical side.

This guide is designed to give you a better understanding of your stove. Perfect for those who are considering stove ownership, have just got a stove or have a stove and want to get a better understanding of it.

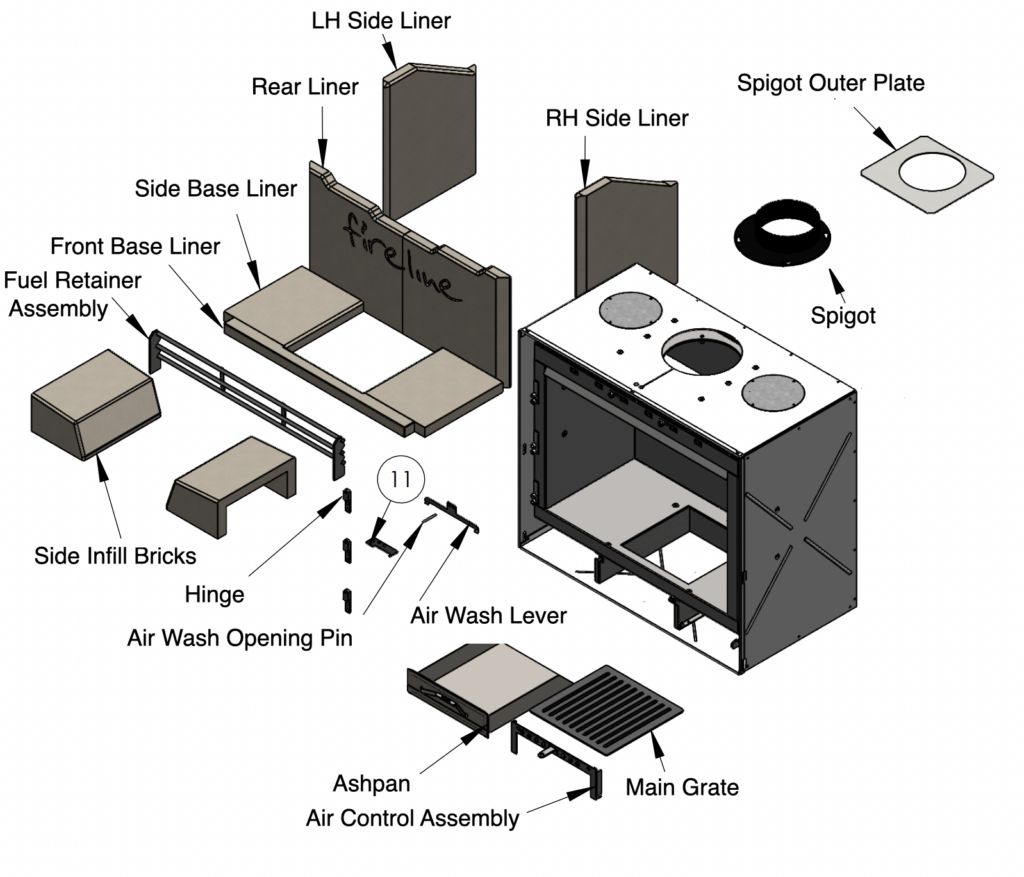

Below is an overview of one of our stoves – A Fireline FPI8. While different stoves vary, this exploded diagram gives a good overview of a general stove anatomy.

Here is a more glossary-based overview of a stove.

Air wash – An arrangement whereby the flow of secondary air into the firebox is directed down the glass with the intention of creating a laminar flow to reduce combustion residues depositing on the glass panel itself. The result is a clearer view of the fire and a significantly reduced requirement to clean the glass panel.

Ash pan, ash box – Common in multi-fuel and coal stoves is the ashpan for collection of ash fuel residues during and after burning. It is manufactured from corrosion-resistant steel or stainless steel and often incorporates an adaptor for handling with a tool or other means of lifting out of the stove. Sometimes provided in better specification wood burners.

Air control, air spinner, air slider, air lever – A control device regulating the intake of air into the combustion chamber of the stove. An air control is used for primary, secondary and tertiary air or a single control can be used for all air flows depending upon the sophistication of the stove design. It may be provided by a slider, rotary knob or lever or a combination of several different principles.

Baffle plate, throat plate, firebox top plate, deflector plate – A very important part of firebox shaping and elongating flame and gas flow path in order to improve combustion efficiency is the baffle plate that usually forms the roof of the burn chamber. It is most commonly made from steel or stainless steel, with refractory materials such as vermiculite board also being used. Better-designed stoves have easily removable baffles that allow easy soot removal and sweeping of the flue through the stove firebox. A baffle plate is sacrificial in that it will erode over time.

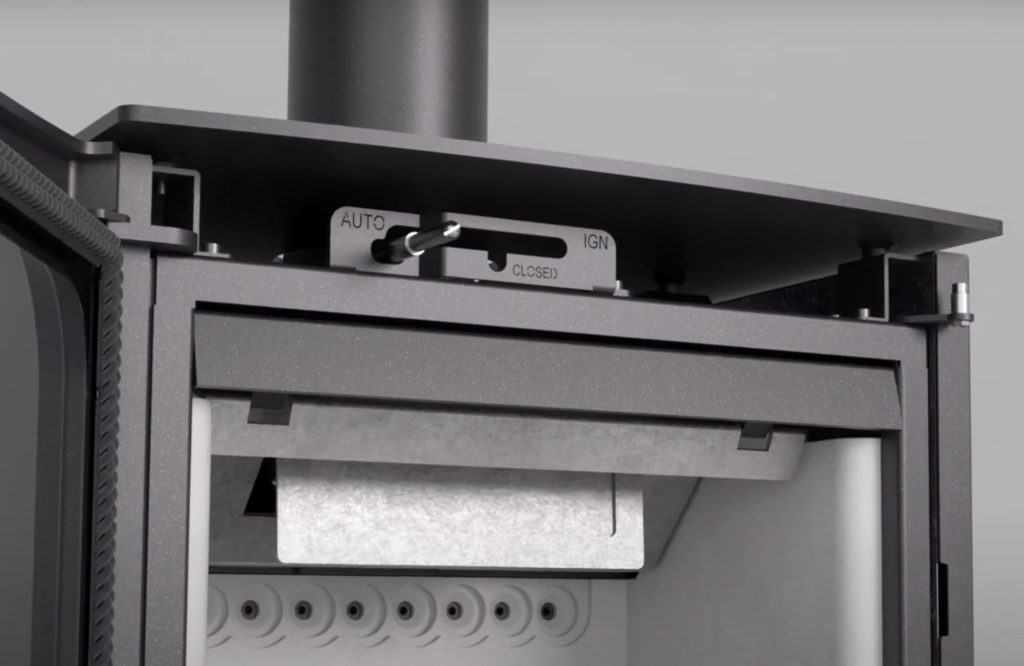

Active Baffle. The Active Baffle is a unique system designed by Charlton & Jenrick and significantly increases stove efficiency. You are able to switch between desired settings via an operating rod. It’s also easily removable for maintenance. Once the active baffle is in the ignition position, the baffle is open fully. This allows the initiation heat directly into the flue for quicker starting and fewer emissions. The auto option on the active baffle is a key benefit of the system, as it closes when the door is closed and opens again when the door opens.

Here is a short video on our Active Baffle:

Burn chamber, combustion chamber – the area within the stove firebox usually defined by the grate or firebase, side and rear firebox liners or firebricks and a baffle plate above. A fuel retainer of some kind is usually provided at the front. The fire itself is situated here. Modern stoves typically have a large glass panelled door in the front of the burn chamber to allow viewing of the fire.

Cooktop – A specially adapted top plate for cooking purposes, sometimes facilitating direct food contact with the plate. Usually made from iron, steel or soapstone materials.

Flue collar, flue spigot, flue connector – The ring-shaped connector that allows a standard flue pipe to connect to the stove firebox at the top or rear. Often manufactured from cast iron or steel and thick in cross-section to ensure that its lifetime is adequate in the presence of corrosive combustion residues. Commonly bolted in place on the stove body to be easily replaceable.

Firebox – The main body construction of the stove that incorporates the actual burning chamber within it. Materials employed are usually steel or cast iron.

Flue Pipe – The pipe that takes the flue gases away from the stove and into the atmosphere at a high level. Usually, it refers to manufactured components rather than brick-built chimneys where the flue way is inside the chimney stack.

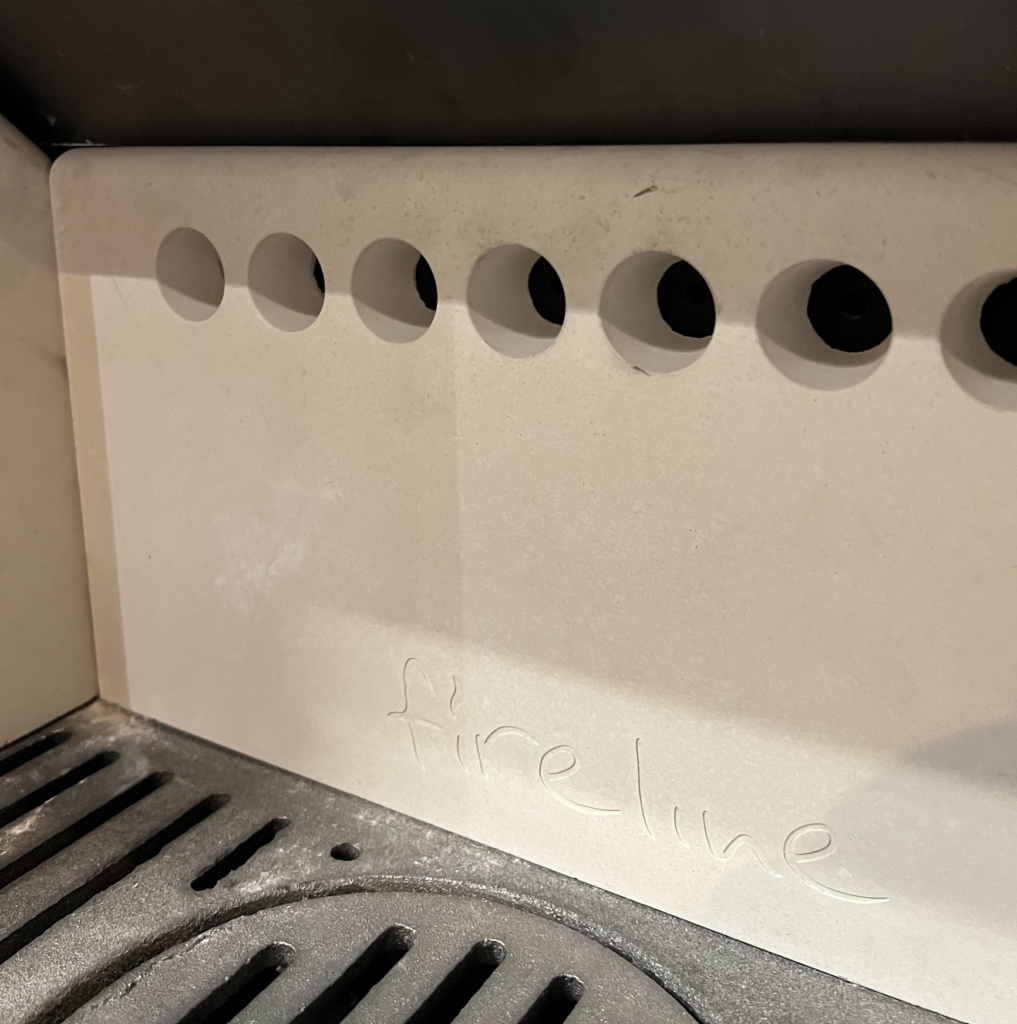

Firebox liners, firebricks, firebox cheeks – These items are commonly made from vermiculite board, refractory firebrick or castable refractory ceramic, depending on the model. They are provided to contain the burning materials and protect the metal construction of the firebox itself from decay and damage. They are sacrificial in that they will wear, crack and erode over time but are repairable with fire cement and replaceable when worn out. The lifetime of firebox linings is very much dependent upon fuels and burning technique and rate. The materials employed are often insulating in their characteristics and reflect heat back into the fire bed to improve combustion conditions and can be replaced. The lifetime of a baffle plate is very much dependent upon fuels used, burning technique and rate.

Fuel retainer, log guard, coal catcher – A device fitted at the front of the burn chamber to retain the burning fuel and char ember bed in place when the door is opened for re-fuelling.

Grate, firebars – The set of cast iron bars provided on which to build the fire. Air spaces are allowed through the grate to admit primary air into the base of the fuel if required. Dedicated wood burners usually don’t have a conventional grate, but multifuel stoves do. The grate is sometimes provided with moveable sections to help drop ash from the fuel bed into the ash pan. The grate is sacrificial in that it will erode over time and can be replaced. The lifetime of a grate is very much dependent upon fuels and burning technique and rate.

Glass Panel – The glass fire viewing panel provided most often in the door of the stove is not, in fact, common glass but a translucent ceramic. Standard or even heat-resisting glass is unable to cope with the thermal expansion stresses created by a solid fuel. Only when transparent ceramic panels became available (developed from ceramic hob glass materials) did large glass viewing panels become practical for domestic wood-burning stoves.

Gasket – A sealing device, usually made from ceramic or glass fibre in stoves for heat resistance and typically flat in appearance, such as 3mm thick gasket paper. Compresses between bolted or clamped components to give an air-tight seal in areas like glass frames, doors and air intake boxes.

Heat exchanger – An additional component or module with enhanced surface area to transfer more heat from the products of combustion into the room air.

Primary air – A flow of air into the fuel bed itself, usually from underneath. Essential for coal and briquette smokeless fuels, usually unnecessary for wood burning when it can remain fully closed.

Rope seal – Typically made from glass fibres woven into a sleeve around a stranded fibre packing core. It may also be made from ceramic fibres for very high heat tolerance. Cemented or clipped into position in a groove where it can create a seal between two components like a door and stove body.

Secondary air – This is the flow of air into the firebox above the fuel bed, usually employed to keep the glass panel clean as an air wash and allow continued combustion above the layer of burning fuel.

Tertiary air – A flow of air injected into the hot burning zone above the actual fire, commonly at the rear of the firebox, to combine with the secondary air to ensure combustion is as complete as possible. Tertiary air is really secondary air by another route. Often, a fixed aperture controls the admission of tertiary air, although some stoves also have an air control for this feature.

Tertiary air profiling – An innovation invented by Peter Mintoft and exclusive to Charlton & Jenrick, this system of increasing the cross-sectional area of the tertiary air inlets within the firebox allows much improved turbulent mixing of the fresh oxygen-rich incoming air and gases produced by the fuel pieces rising up within the hot upper firebox zone and patented in most of the world, including Europe and China.

Looking to buy a wood-burning stove? You are able to view our range of wood-burning stoves here.