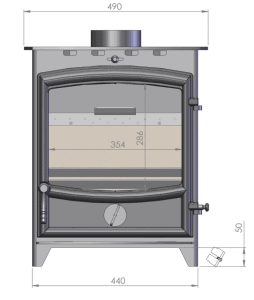

Wood burns as a solid and also a gas, which can be quite a challenge from a design perspective. Over the years we have invested a significant amount of resources and time in increasing the efficiency of our wood burning stoves. This article looks at the various technical elements, which are needed to ensure a high efficiency burn in a Charlton & Jenrick stove.

.

- A High Temperature– Our stoves are designed to generate a high enough temperature so the hydrocarbon gases can ignite and combust fully. In organic chemistry terms, a hydrocarbon is an organic compound consisting of entirely hydrogen and carbon, and is a byproduct during the burning process of wood.

.

A key part to achieving this high temperature is retaining heat within the fuel bed and creating turbulence in the fire box for the oxygen to assist breaking down the wood itself, which is outlined more below.

. - Turbulence– Turbulence in the firebox is needed to ensure the hydrocarbon gases and oxygen in the air supply can mix together to create heat. Without the necessary turbulence, the mix of the hydrocarbons and oxygen will be limited, which will reduce the completeness of combustion and thereby heat output and overall efficiency of a stove. In terms of firebox design, turbulence is achieved by creating excellent circulation of gases around the firebox during initial laboratory development testing.

. - Oxygen– A firebox is carefully designed to provide just enough oxygen for a fire. This is done by preventing excess air intake that bypasses the combustion zones within the firebox. Too much air supply can ultimately cool and even carry the hydrocarbons away from the firebox as unburned smoke and gas. Too little oxygen will cause the fire to slumber, and produce an inefficient level of heat with potentially high emissions of partly combusted byproducts and tar in the chimney.

. - Time– Allowing the hydrocarbons sufficient time in the right conditions to ignite is essential. The reason for this is to ensure they produce the required level of heat and minimal unburned emissions, which contributes to the high level of efficiency that is seen in our stoves.

As a company we are aiming to get as close to 100% efficiency as possible, by extracting maximum heat output from each kilogram of fuel used. This approach not only means lower fuel costs for you due to the increased efficiency, but also it is much better for the environment as you will be burning less, and what you burn will burn in a much more complete and efficient way.

Fuel Issues:

We have spoken at length in the past about the need for the right quality fuel – view our wood burning guide for more info. Fuel is the one variable you can have complete control over when it comes to achieving maximum stove efficiency. Perhaps the most significant element, which impacts on fuel quality is moisture levels. Excessive moisture can really impact on the combustion of the wood, and the corresponding efficiency and heat output. If you are unsure you can check the moisture of wood with a moisture meter, which is always advised before burning wood if you are unsure of its moisture content.

The ideal level of moisture in fire wood is around 10-20%. Up to 60% of a logs weight can be water. Seasoning or kiln drying wood is essential before it is used on a wood burning stove, to reduce its moisture content to around or below the desired 20%. You can learn the key differences between seasoning and kiln drying in a previous news article we have produced.

And If You Burn Green Wood – What Happens?

If you do go against advice and try and burn green (wet) wood you will be impacting significantly on the stoves efficiency. Lets assume you try and burn a green 1kg log. This could be potentially made up of 0.6kg of water (60% moisture). When you try and burn this, what will firstly happen is that the excessive water will need to be boiled off before the wood can burn efficiently. This will have an impact on the temperature inside the firebox. This lower temperature, as you are effectively boiling the logs, will stop the previously mentioned hydrocarbons from burning. The net result is a poor flame, a poor heat output and reduced stove efficiency – not to mention potentially damaging condensation, tar and build up in the chimney.

What About Overly Dry Wood?

Overly dry wood, which has a moisture content well below the desired 10-20% is not good either. It will burn too fast, and produce too much heat. The fast burning of the hydrocarbons will cause an additional demand for more oxygen. This will prevent the full and efficient combustion of the gases. Smoke and excessive pollution will be the end result.

You wouldn’t put a substandard fuel in your car, so why risk it in your stove?

To view our range of high efficiency wood burning stoves, visit our gallery or download a brochure